A Technical Guide for Selecting Reliable Seals in Extreme Heat (-50°C to 300°C)

High-temperature silicone seals are vital for industrial safety and equipment longevity. For instance, a leading automotive manufacturer faced recurring engine oil leaks due to seal degradation under extreme heat, resulting in over $1 million in annual maintenance costs. At SYDNIX Electronics, we specialize in high-performance sealing solutions. This guide unpacks five critical performance indicators for selecting silicone seals that withstand harsh thermal environments, helping you avoid costly downtime and safety risks.

1. Temperature Range: Static vs. Dynamic Applications

- Static Applications (e.g., oven doors):

- Continuous Operating Range: Standard silicone: -50°C to 200°C; phenyl silicone variants: up to 300°C.

- Case Study: A global industrial oven manufacturer extended seal lifespan by 3x using SYDNIX phenyl silicone seals.

- Dynamic Applications (e.g., engine components):

- Frictional heat reduces effective temperature tolerance by 20–30°C below nominal ratings.

- Recommendation: Opt for high tear-strength silicone (≥25 kN/m) to resist mechanical stress.

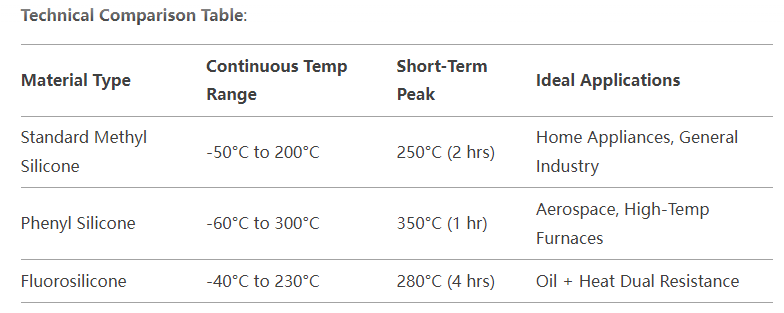

- Technical Comparison Table:

2. Compression Set: Ensuring Long-Term Seal Integrity

- Testing Standard (ASTM D395):

- Seals compressed by 25% at elevated temperatures for 22 hours; ≤20% deformation post-recovery is industry-accepted.

- SYDNIX Performance: ≤15% deformation at 150°C.

- Process Innovation:

- Two-Stage Vulcanization: Reduces volatile residues, enhancing elasticity.

- Client Feedback: A chemical plant extended seal replacement intervals from 6 months to 2 years using SYDNIX’s optimized seals.

3. Thermal Aging Resistance: Predicting Service Life

- Aging Test Protocol (GB/T 3512):

- Accelerated aging (e.g., 200°C × 72 hours) measures tensile strength retention.

- Premium silicones retain ≥80% tensile strength post-testing.

- Material Enhancements:

- Heat Stabilizers: Additives like iron oxide red mitigate free radical damage.

- Custom Testing: SYDNIX offers client-specific aging simulations (temperature/duration) with detailed reports.

4. Chemical Compatibility: Surviving Harsh Media

- Common Failures:

- Heat accelerates reactions with oils, acids, or alkalis, causing swelling or cracking.

- Selection Strategy:

- Oil Resistance: Fluorosilicone for engine oil or hydraulic fluid exposure.

- Acid/Alkali Resistance: High-purity silicone + PTFE coatings (e.g., food processing equipment).

Case Study:

A food processing client using standard seals experienced 12% volume swelling in 150°C steam with mild acid cleaners. Switching to SYDNIX acid-resistant seals reduced swelling to <3%, eliminating unplanned downtime.

5. Installation & Groove Design: Preventing Mechanical Failure

- Optimal Compression Ratios:

- Static Seals: 15–25%

- Dynamic Seals: 10–15% (excessive compression increases friction/heat).

- Groove Design Guidelines:

- Width = Seal Cross-Section × 1.3

- Depth = Seal Cross-Section × 0.8

- Free Engineering Support: SYDNIX provides groove design optimization within 48 hours of CAD submission.