Why deburring matters in O-ring manufacturing

During the O-ring manufacturing process, small flashes or burrs are often left behind after molding. If not removed properly, these imperfections can cause sealing failures, leakage, assembly issues, or shorten product lifespan. That’s why O-ring deburring (also called rubber seal deflashing) is a critical finishing step for reliable performance.

This article introduces the most common rubber seal deburring methods and compares their pros and cons, helping you understand which process works best for your sealing products.

1. Manual Deburring (Hand Trimming)

How it works: Operators use knives, scissors, or abrasive tools to manually trim excess flash.

Pros: Flexible, suitable for small batches, prototypes, or irregular shapes.

Cons: Low efficiency, labor-intensive, inconsistent results.

2. Vibration / Tumbling Deburring

How it works: O-rings are placed in a vibrating or tumbling machine with abrasive media to gradually remove burrs.

Pros: Cost-effective for medium runs, relatively simple process.

Cons: Limited precision, may affect the surface, not ideal for high-quality EPDM O-rings.

3. Cryogenic Deburring (Nitrogen Deflashing)

How it works: Products are frozen with liquid nitrogen so burrs become brittle. High-speed media blasting then removes the frozen flash.

Pros: Highly efficient, consistent, excellent for large-scale EPDM O-ring deburring and complex geometries.

Cons: Higher equipment and operating cost, less suitable for very large or very small rubber seals.

4. Mechanical Trimming (Lathe Cutting)

How it works: O-rings or gaskets are fixed in a trimming machine, where blades cut away flash.

Pros: Accurate and reliable for round parts such as standard O-rings.

Cons: Requires tooling, less flexible for irregular shapes.

5. Die Trimming (Punch Trimming)

How it works: Custom trimming dies punch away burrs from the rubber part.

Pros: Very fast and efficient for mass production of rubber seals.

Cons: High tooling cost, only suitable for regular shapes.

6. Laser Deburring

How it works: Laser beams precisely ablate or burn off burrs.

Pros: High precision, contact-free, ideal for micro or complex O-rings.

Cons: Very high cost, slower process, may affect rubber surface properties.

7. Water Jet Deburring

How it works: High-pressure water jets remove burrs without damaging the base material.

Pros: Clean, environmentally friendly, suitable for soft rubber gaskets.

Cons: Limited effectiveness on harder rubber flash, higher equipment cost.

8. Chemical Deburring

How it works: Specialized chemicals dissolve or soften burrs before washing them away.

Pros: Effective for hidden or complex geometries.

Cons: Environmental and safety concerns, not suitable for food- or medical-grade O-rings.

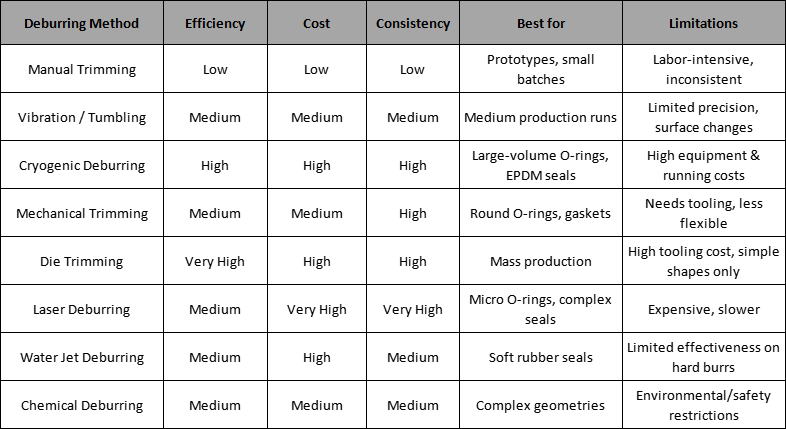

Comparison Table of Deburring Methods

Choosing the Right O-Ring Deburring Method

There is no single “best way to remove O-ring flash” for every situation. The choice depends on material type (EPDM, NBR, FKM, silicone), product geometry, batch volume, cost, and quality requirements.

At SYDNIX Electronics, we use multiple rubber seal deburring techniques — including manual, mechanical, vibration, and cryogenic deburring — to ensure clean and precise finishing for O-rings, gaskets, and custom rubber seals. Our flexible approach allows us to meet different customer needs, whether for industrial O-rings, automotive sealing parts, or custom rubber gaskets.

If you are looking for a reliable partner in O-ring manufacturing and finishing, contact us to discuss the best solution for your sealing products.